Research Areas

Advanced Manufacturing

In today’s world, the field of advanced manufacturing is experiencing constant disruption due to innovations of new technologies, processes and process-control capabilities to deliver ever-changing performance demands. The field made major transformations while moving from bulk manufacturing (i.e. casting and forging) to additive and hybrid manufacturing era. Currently, we are stepping towards the domain of convergent manufacturing which combines virtual manufacturing, manufacturing processes including bulk, additive, subtractive and transformative, process monitoring and control in one platform or process to yield functional devices and components. Our objective is to develop functional parts by leveraging multi-process capabilities and understand process-microstructure-property relationship of manufactured components for select applications ranging from nuclear, defense and space applications.

Ongoing Projects

DREAM-TEAM: Developing a Robust Ecosystem for Additive Manufacturing of Tungsten for Extreme Applications and Management (Funding Agency: US Department of Energy, Research Collaborators: University of North Dakota, Ames National Laboratory, Argonne National Laboratory, Oak Ridge National Laboratory)

Previous Projects

Materials and Surface Processing

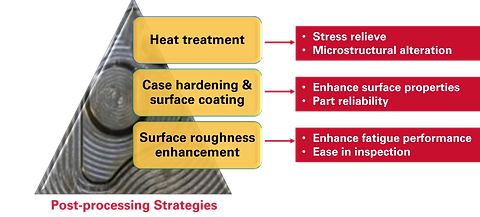

Metal parts fabricated via additive, hybrid or convergent manufacturing routes often possess deleterious phases, non-homogeneous microstructure and other characteristics which can affect their bulk mechanical properties in-particular tensile, toughness and fatigue performances. As a result, proper materials processing is required to ‘reset’ or modify the microstructural attributes to enhance target mechanical properties. On the other hand, surface properties can be tweaked by development of novel surface protective coatings, case hardening heat treatments on both additively and conventionally manufactured samples. We pursue different routes to maintain isotropy and homogeneity in large scale additively manufactured components through advanced materials processing routes. In case of surface processing, we focus on functionally graded product development, in-situ and ex-situ impact treatments and hard-facing coating development to enhance reliability of functional components fabricated via both additive and conventional manufacturing routes. One of the major challenges of metal additive manufacturing is increased surface roughness of printed parts. We are working on developing sustainable and effective novel processes to reduce surface roughness of printed parts which can deployed for both external and internal intricate surface regions.

Ongoing Projects

Surface Science and Tribology

Lubricants, consisting of base oils and additives play a crucial role in enhancing the component reliability by reducing friction and wear. From industrial application viewpoint, there is a need to produce graphene in large-scale instead of conventional smaller quantities. Additional limitations include lack of technological process economic feasibility data, product yields, and analysis of target markets. We are working on coal-based graphene additized and bio-based multifunctional lubricant developments. Friction and wear behavior of additive manufactured components can be significantly different as compared to conventionally fabricated parts. We focus on fundamental studies to reveal differences in wear mechanisms to develop next generation advanced manufactured parts can provide enhanced operational reliability. We concentrate on both sliding and rolling-sliding contact phenomena which are associated with major failure modes observed in drivetrain components (i.e. gears and bearings).

Ongoing Projects

Previous Projects